Levitra Soft

General Information about Levitra Soft

The energetic ingredient in Levitra Soft is vardenafil, which has been confirmed to be highly effective in treating ED. It works by relaxing the smooth muscle tissue in the blood vessels of the penis, permitting them to widen and improve blood flow. This results in a firmer and longer-lasting erection, enabling men to interact in sexual activity and improve their general sexual satisfaction.

Levitra Soft has a quick onset of motion, with results being felt inside 15 minutes of taking the delicate pill. This makes it a extra handy possibility in comparability with other ED medicines, which may take up to an hour to begin working. It additionally has a longer duration of action, with effects lasting for up to 5 hours. This allows males to engage in sexual exercise with out having to fret about timing the medicine completely.

A gentle tab version of the unique Levitra, this treatment is specially formulated for easy and handy consumption. It comes within the form of a gentle pill that dissolves quickly and simply within the mouth without the necessity for water. This makes it a more discreet and sensible possibility, particularly for males who've difficulty swallowing pills.

In conclusion, Levitra Soft is a prescription medicine that offers males with ED a discreet, handy, and efficient treatment option. With its fast onset of action and longer length of results, it helps improve sexual satisfaction and confidence in men. Remember to always consult with a doctor and take the medicine as prescribed for the most effective and most secure results.

It works by growing blood circulate to the penis, resulting in a firmer and longer-lasting erection.

Levitra Soft is a prescription medication that's particularly designed to deal with ED. It belongs to a category of drugs referred to as phosphodiesterase-5 (PDE5) inhibitors, which work by rising blood flow to the penis. This helps males to realize and maintain an erection when they're sexually stimulated.

Erectile dysfunction (ED) is a common situation that affects tens of millions of males worldwide. It refers back to the inability to attain or maintain an erection sufficient for sexual activity. While this can be a source of embarrassment and frustration for so much of males, there are effective remedies obtainable, and one such remedy is Levitra Soft.

Levitra Soft is a protected and efficient possibility for men experiencing ED. However, it is necessary to consult with a well being care provider earlier than starting any new medication. They will be ready to assess your condition and decide if Levitra Soft is the proper treatment for you, and if so, what the appropriate dosage is predicated on your individual needs.

One necessary factor to note is that Levitra Soft solely works when a man is sexually aroused. It does not cause automatic erections, and due to this fact, sexual stimulation continues to be needed for the medication to take effect. This means that males can have control over their erections, and they can have interaction in sexual activity at a time that feels right for them and their partner.

As with any medication, there are some unwanted aspect effects related to Levitra Soft. The most common side effects embrace headache, dizziness, flushing, and nasal congestion. However, these side effects are usually delicate and short-term. In uncommon instances, some males may expertise more severe side effects such as modifications in imaginative and prescient, sudden hearing loss, or an erection that lasts longer than 4 hours. If any of those happen, it is necessary to seek medical attention immediately.

For sterilization purposes erectile dysfunction treatment hyderabad buy 20 mg levitra soft with amex, exposure times can be long, but the Electromagnetic radiation radiation results when the nucleus still has too much energy even after the emission of or particles. This energy is dissipated in the form of very short wavelength radiation which, as it has no mass or charge, travels with the speed of light, penetrating even sheets of lead. Although travelling in a wave form, radiation behaves as if it is composed of discrete packets of energy called quanta (photons). They have properties similar to those of -rays despite originating from a shift in electron energy rather than from the nucleus. Units of radioactivity the unit of activity is the becquerel (Bq), which is equal to one nuclear transformation per second. The energy of radiation is measured in electronvolts (eV) or millions of electronvolts (MeV). In this case the ionizing radiation is directly responsible for the damage by causing a direct hit on a sensitive target molecule. The passage of ionizing radiation through water causes ionization along and immediately next to the track and the formation of free radicals and peroxides. These peroxides and free radicals are highly reactive and destructive and are responsible for both the killing capability and the ability to modify the properties of polymers. Resistance to radiation is genetically determined, and a particularly resistant bacterium called Deinococcus radiodurans can withstand a radiation dose up to 5000 Gy, compared with Escherichia coli, which is killed by 800 Gy. It is worth noting that microbial products such as endotoxins will not be inactivated by normal doses of ionizing radiation. Oxygen has already been mentioned as having a significant influence on the antimicrobial effects of radiation, as increased levels of hydroperoxyl radicals lead to marked increases in kill. The presence of moisture will also influence sensitivity, with dehydration causing an increase in resistance owing to an indirect effect on the formation and mobility of free radicals. Freezing increases radiation resistance owing to the reduction of mobility of free radicals in the menstruum, preventing them from diffusing to sites of action at the cell membrane. A variety of organic materials provide a protective environment for microorganisms, and comparison of radiation resistance is greatly complicated by different complexities of the media used. Some naturally occurring materials, particularly foods, may have a profound protective effect on contaminant bacteria. A wide variety of gaseous agents has been used for their antimicrobial properties, and a few of the major ones will be considered here. Its odour is reported as being rather pleasant, although the levels at which it is detected in the atmosphere (700 ppm) greatly exceed the 5 ppm maximum safety limit for humans. Toxicity problems include burns and blistering if the material comes into contact with the skin, whereas inhalation results in lachrymation, headache, dizziness and vomiting. Great care must be taken to ensure the removal of residual ethylene oxide from treated products. Explosive mixtures are formed when ethylene oxide is mixed with air at any concentration above 3%, and this is especially dangerous if the gas mixture is confined. The addition of carbon dioxide or fluorinated hydrocarbons will eliminate this risk, and for sterilization purposes, gas mixtures of 10% ethylene oxide and 90% carbon dioxide are typically used. Ethylene oxide is extremely effective at killing microorganisms, and its activity is related to its action as an alkylating agent. Reactive hydrogen atoms on hydroxyl, carboxyl, sulfhydryl and amino groups can all be replaced with hydroxyethyl groups, thereby interfering with a wide range of metabolic activities. Ethylene oxide inactivates the complete spectrum of microorganisms, including endospores and viruses. The difference in resistance between endosporeforming bacteria and vegetative cells is only of the order of 5 to 10 times, compared with severalthousand-fold differences with other physical and chemical processes. In addition, no microorganism of genetically determined high resistance has been found. The formation of aggregates of cells will result in those cells at the centre of the aggregate surviving an otherwise lethal dose of radiation. Similarly, microorganisms suspended in water withstand considerably higher doses of radiation than in the dry state, owing to lack of penetration of the radiation. Suspension of bacteria in broth containing organic matter such as proteins increases the resistance of the cells still further. The stage of growth of the culture will affect the sensitivity of the cells, with maximum sensitivity being shown during the logarithmic phase. Other factors shown to influence radiation resistance include pH, temperature and humidity, although the effect of the last parameter is still somewhat confused. Factors affecting the activity of ethylene oxide the bactericidal activity of ethylene oxide is proportional to the partial pressure of the gas in the reaction chamber, the exposure time, the treatment temperature, and level and type of contamination. At room temperature, the time taken to reduce the initial concentration of cells by 90% can be very slow. For this reason, elevated temperatures of 50 °C to 60°C are recommended, and these result in greatly increased rates of kill. Concentrations of ethylene oxide between 500 mg L-1 and 1000 mg L-1 are usually used. Microorganisms may be protected from the action of ethylene oxide by occlusion within crystalline material or when coated with organic matter or salts. Biological indicators used to test the efficacy of ethylene oxide treatment employ spores of B. Its bactericidal powers are superior to those of ethylene oxide (concentrations of 3 mg L-1 to 10 mg L-1 are effective) but it has weak penetrating power and is really only a surface bactericide.

These formulations are similar to those that are used to fill soft gelatin capsules but differ in one important respect: they can have melting points higher than 35 °C erectile dysfunction caused by vascular disease order levitra soft toronto, which is the maximum for soft capsules because this is the temperature used by the sealing rollers during their manufacture. Nonaqueous liquids, which Powder formulation Most products that are used to fill capsules are formulated as powders. These are typically mixtures of the active pharmaceutical ingredient together with a combination of different types of excipients (Jones, 1995; Table 33. The ones selected depend on several factors: · the properties of the active drug: its dose, solubility, particle size and shape; · the filling machine to be used; and · the size of capsule to be used. The latter factor defines the free space inside the capsule that is available to the formulator (Jones, 1998). Formulation for release of active ingredients the first stage in release from capsules is disintegration of the capsule shell. When gelatin capsules are placed in a suitable liquid at body temperature, 37 °C, they start to dissolve and within 1 minute the shell will split, usually at the ends. With a properly formulated product, the contents will start to empty out before all the gelatin has dissolved. The official tests for disintegration and dissolution were originally designed for tablets. Capsules have very different physical properties, and after the contents have emptied, the gelatin pieces remaining will adhere strongly to metal surfaces and may confuse the end point of the test. Hypromellose capsules take a longer time to the first split, but after this tend to disperse faster than gelatin capsules (Missaghi & Fasshi, 2006). The literature shows that the rate-controlling step in capsule disintegration and product release is the formulation of the contents, which ideally should be hydrophilic and dispersible (Jones, 1987). The factors that can be modified to make the active ingredients readily available depend on their properties and those of any excipients being used. The active ingredients have a fixed set of physicochemical properties, which, except for the particle size, are out of the control of the formulator. It has been shown that the particle size influences the rate of absorption for several compounds formulated into capsules. This can be explained simply by the fact that the dissolution rate is directly proportional to the surface area of the particles: the smaller the particle, the greater the relative surface area. However, this is not a panacea for formulation problems because small particles tend to aggregate and the effect is lost. This is related to the packing of particles and is a measure of how well the fluid can penetrate into the mass. Diluents are the excipients that are usually present in the greatest concentration in a formulation. They were classically defined as inert materials added to formulated are low-dose potent ones, which in the final formulation occupy only a small percentage of the total volume (< 20%) and so the properties of the mixture will be governed by the excipients chosen. Formulation for filling properties There are three formulation: glidant); main factors in powder · good flow (using a free-flowing diluent and · no adhesion (using a lubricant); and · cohesion (plug-forming diluent). The powder bed, from which the dose is measured, needs to be homogeneous and packed reproducibly in order to achieve uniform fill weights. Packing is assisted by mechanical devices or suction pads on the filling machines. Low-dose active ingredients can be made to flow well by mixing them with free-flowing diluents. The diluent is also chosen for its plug-forming properties: the diluents most frequently used are lactose, starch 1500 and microcrystalline cellulose. When space is limited, then either glidants, which are materials that reduce interparticulate friction, such as colloidal silicon dioxide, or lubricants, which are materials that reduce powder-to-metal adhesion. A capsule was reformulated that contained phenytoin (diphenylhydantoin), which is used for the treatment of epilepsy and is taken long term. In the months following this change, there was an upsurge in reports of side effects similar to overdosing of product. The change to lactose gave much higher blood levels of the drug, which was probably due to it being readily soluble whereas calcium sulfate is not. The diluent used should be chosen in relation to the solubility of the active ingredient. If a soluble diluent such as lactose is added to a poorly or insoluble compound, it will make the powder mass more hydrophilic, enabling it to break up more readily on capsule shell disintegration. The converse is also true: drugs that are readily soluble are best mixed with insoluble diluents such as starch or microcrystalline cellulose, because they help the powder mass to break up without interfering with their solubility in the medium. Some excipients, such as lubricants and glidants, are added to formulations to improve their filling properties and these can sometimes have an effect on release. The important thing to avoid in formulations is materials that tend to make the mass more hydrophobic. The most commonly used lubricant for both encapsulation and tableting is magnesium stearate. They found that the dissolution rate was greatly reduced at the highest level of magnesium stearate, which they explained was due to the poor wetting of the powder mass. However, hydrophobic additives are not always deleterious because they reduce the cohesiveness of the powder mass. They found that for the larger particles (180 µm to 355 µm), the addition of magnesium stearate reduced the rate, whilst for the smaller particles (< 75 µm), it increased the rate.

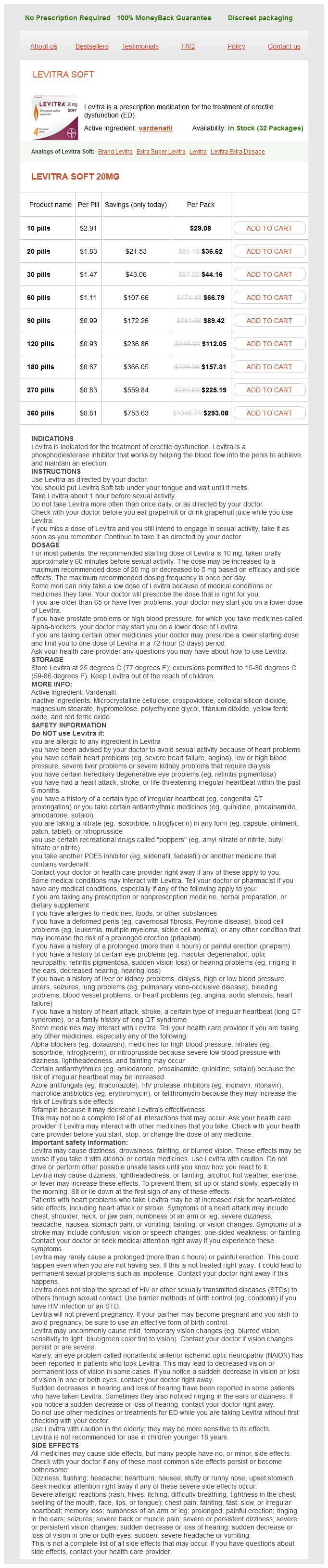

Levitra Soft Dosage and Price

Levitra Soft 20mg

- 10 pills - $29.08

- 20 pills - $36.62

- 30 pills - $44.16

- 60 pills - $66.79

- 90 pills - $89.42

- 120 pills - $112.05

- 180 pills - $157.31

- 270 pills - $225.19

- 360 pills - $293.08

This change in electrical resistance can be recorded and calibrated in terms of a force signal erectile dysfunction caused by radical prostatectomy buy 20 mg levitra soft with visa. These are devices which emit an electrical charge when loaded, the magnitude of which is proportional to the applied force. When the rod moves within the tube, a signal is obtained which directly reflects the position of the rod. Displacement transducers are necessarily mounted some distance from the punch tip. There is therefore a difference in the position given by the transducer and the real position of the punch tip owing to deformation of the punch along the distance between its tip and the connection point of the transducer. The signals from the force and displacement transducers are normally amplified and sampled into a computer. After conversion into digital form, the signals are transformed into physically relevant units. To obtain reliable data, the calibration of the signals, the resolution of the measuring systems and the reproducibility of the values must be carefully considered. In addition, the surface of punches and dies may be coated with a thin layer of another metal, such as chrome, to modify its surface properties, such as hardness and corrosiveness. Punches and dies are precision tools and they should thus be handled and stored with care. Tooling inspection programmes should thus be used in the development and production of tablets. Technical problems during tableting A number of technical problems can arise during the tableting procedure, amongst which the most important are: Tablet tooling Tablets are formed in a variety of shapes. The most common tablet shapes are circular, oval and oblong, but tablets may also have other shapes, such as triangular or quadratic. From a side view, tablets may be flat or convex and with or without bevelled edges. Break marks (or break lines) are used to facilitate breaking of tablets in a controlled way to ensure reproducible doses. Markings are used to facilitate identification of a preparation and are of two types: embossed and debossed. Debossed markings are indented into the tablet and embossed markings are raised on the tablet surface. The size, shape and appearance of a tablet formed by powder compaction are controlled by the set of tools and by tooling design; a large variation in tablet size, shape and appearance can thus be obtained. Punches and dies for rotary presses are designed in a standardized way, and standard configurations and terms are in use. The terminology used in describing the punches includes head, neck, barrel, stem and tip and that used in describing the die includes face, chamfer and bore. Because of the high forces applied to the powder bed, tools may be damaged and under normal use they become worn. The toughness, wear resistance and corrosiveness differ between different types of · · · · high weight and dose variation of the tablets; low mechanical strength of the tablets; capping and lamination of the tablets; adhesion or sticking of powder material to punch tips; and · high friction during tablet ejection. Such problems are related to the properties of the powder intended to be formed into tablets and also to the design and conditions of the press and the tooling. They should therefore be avoided by ensuring that the powder possesses adequate technical properties and also by the use of a suitable, well-conditioned tablet press. Important technical properties of a powder that must be controlled to ensure the success of a tableting operation are: · · · · homogeneity and segregation tendency; flowability; compression properties and compactability; and friction and adhesion properties. The technical properties of the powder are controlled by the ingredients of the formulation. The precompaction processing often consists of a series of unit operations in sequence. For further details of these procedures see Chapters 10, 11, 28 and 29 respectively. Granulation of a fine powder is a common means used to preserve the fineness of the drug within larger particles that are suitable for tableting (see later), and granulation procedures are traditionally in common use in preparing a powder for tableting. To save time and energy, precompaction processing without a particle size enlargement operation is chosen if possible. This procedure is called tablet production by direct compression or direct compaction. Different procedures may be used for granulation, amongst which the most important are the use of convective mixers, fluidized-bed dryers, spray-dryers and compaction machines. Chapter 28 discusses granulation in some detail, but the process is summarized here in the context of tableting. Granulation by convective mixing Agitation of a powder by convection in the presence of a liquid, followed by drying, is the main procedure for the preparation of pharmaceutical granules. This is often considered to be the most effective means in terms of production time and cost to prepare good-quality granules. As the components are often cohesive powders, a convective mixer operating at high intensity is normally used (a high-shear mixer). The drugs to be used in tablet formulations may have hydrophobic surfaces and thus are not wetted easily by water. In order to facilitate water-based wet granulation of such powders, a surface-active agent may be added to the granulation liquid used during wet massing of the powder. Improved wetting may promote a more uniform liquid distribution and better granule growth during wet granulation.